Add to Cart

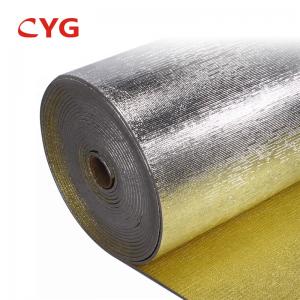

Cross-linked Closed Cell Polyethylene Foam

Polyethylene foam is a durable, lightweight, resilient, closed-cell material. It is often used for insulations,construction,vehicle,culture/sports, packaging and so on, due to its excellent vibration dampening and insulation properties. It also offers high resistance to chemicals and moisture.

Before quote to us,please provide the following information to customized:

Density,thickness,size,color,and so on.

The Spec. of XPE Foam

| Test item | Items | |||||||

| 5 Times | 8 Times | 10 Times | 15 Times | 20 Times | 25 Times | 30 Times | 35 Times | |

| Density kg/m3 | 200±30 | 125±15 | 100±10 | 66.7±8 | 50±6 | 40±4 | 33.3±3 | 28.6±2 |

| Shore Hardness | 60~70 | 50~60 | 45~50 | 35~45 | 30~35 | 25~30 | 18~25 | 13~18 |

| Water absorbtion (23℃±2℃,24h)g/cm2 | ≤0.02 | ≤0.02 | ≤0.03 | ≤0.03 | ≤0.04 | ≤0.04 | ≤0.05 | ≤0.05 |

| Heat conductivity K value w/m.k | ≤0.092 | ≤0.082 | ≤0.072 | ≤0.062 | ≤0.053 | ≤0.047 | ≤0.041 | ≤0.038 |

The Spec. of IXPE Foam

| Test item | Items | |||||||

| 5 Times | 8 Times | 10 Times | 15 Times | 20 Times | 25 Times | 30 Times | 35 Times | |

| Density kg/m3 | 200±30 | 125±15 | 100±10 | 66.7±8 | 50±6 | 40±4 | 33.3±3 | 28.6±2 |

| Shore Hardness | 60~70 | 50~60 | 45~50 | 35~45 | 30~35 | 25~30 | 18~25 | 13~18 |

| Water absorbtion (23℃±2℃,24h)g/cm2 | ≤0.02 | ≤0.02 | ≤0.03 | ≤0.03 | ≤0.04 | ≤0.04 | ≤0.05 | ≤0.05 |

| Heat conductivity K value w/m.k | ≤0.095 | ≤0.084 | ≤0.073 | ≤0.065 | ≤0.055 | ≤0.045 | ≤0.040 | ≤0.040 |

Function

Heat insulation,waterproof,shock absorption,sound insulation

More function

Applications

Insulations

Heating and cooling machines, tanks, reservoirs and insulation materials;central air conditioning, air conditioning with heat insulation, Sound proof,sound-absorbing.

Vehicle

Automotive interior decoration, ceiling, dashboard,cover the old boards, coolers, flooring and other materials.

Construction

Construction, civil engineering field, roof, wall insulation, thermal insulation,cushioning, anti-condensation, waterproof, leak-proof, wallpaper,anti-corrosion materials; various infrastructure construction materials;anti-frost, shock cushioning material; interior decoration,mattress materials,wall sound barriers.

Packaging

Electronics, components, appliances and other demanding protection and packaging materials.

Culture/sports

School teaching materials, children's toys, sporting a variety of mattress,surfboard, swimming with life jackets, float and cushioning materials;kitchen sink mat, bath cap and slippers, hats.

Packaging & Shipping

About CYG

CYG TEFA is the earliest PE foam manufacturing with scale production in China since 2002.Mainly produce XPE FOAM,IXPE FOAM,IXPP FOAM and ESD PRODUCT(Foam type: PE/EVA/PU/EPE/PP Plastic).Annual production capacity is about 6000 tons.2 bases one in Shen zhen and an other in Huzhou,with total 17 production lines.CYG Management control system: Kingdee / OA / Oracle.CYG have a professional team and technology.More than 30 R&D staff.Through the great variety of our products we provide people with a warm and quiet home and working environment.

Certification

Workshop

Exhibition

FAQ

1)What is the difference between polyethylene and polyurethane foam?

Polyethylene is a firm, closed-cell foam.It is also sometimes used as a top layer over softer foam in order to provide better footing while the lower, softer foam adds some shock absorption. What is polyurethane foam? Polyurethane is a softer, open-cell type of foam that is made in varying degrees of firmness.

2)Is polyethylene foam toxic?

Polyethylene is Safe and Non-Toxic

Blocking chemical off-gassing is not so simple.Low density, food-grade polyethylene is safe and non-toxic. It has a simple molecular structure that does not require toxic chemical additives like phthalates and other unsafe plasticizers.

3)How can I know the suitable foam density I need?

A: Our PE foam density is between 25 kg/m3 and 330 kg/m3

We can provide the best solution for you according to the application, Density, hardness, thickness.And The free sample is available for your confirmation and text

4)What's the difference between open and closed cell foam?

A spray insulation is referred to open cell or closed cell because of the difference between the small bubbles (cells) that make up the foam. The cells are pressed together, so air and moisture are unable to get inside the foam. Because of this,closed cell foam is much more rigid and stable than open cell foam.

5)What is the difference between polypropylene and polyethylene?

Monomer of polyethylene is ethylene and monomer of polypropylene is propylene.Polyethylene has a lower melting point compared to the higher melting point of polypropylene. Polypropylene is not as sturdy as polyethylene. Polypropyleneis stiffer and resistant to chemicals and organic solvents compared to polyethylene.